Israeli medical start-up prepares to build a better bone (Times of Israel)

Make no bones about it: A one-of-a-kind factory is going up in northern Israel.

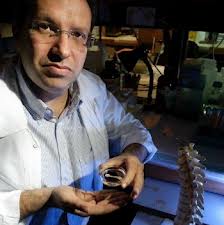

Scientists at the Haifa facility there will manufacture bones for use in bone grafts, and they’ll do so using a new technique — taking live fat cells from patients by liposuction –which, according to its inventor, Dr. Shai Meretzki, will significantly change the way doctors relate to orthopedic problems and bone repairs.

Scientists at the Haifa facility there will manufacture bones for use in bone grafts, and they’ll do so using a new technique — taking live fat cells from patients by liposuction –which, according to its inventor, Dr. Shai Meretzki, will significantly change the way doctors relate to orthopedic problems and bone repairs.

And once his company, Bonus BioGroup, has perfected its method of growing bones in a test tube, Meretzki said, it will also move on to developing joint replacements, which could help billions of older people regain their lost freedom of movement.

“Our bone-regeneration methodology is a powerful tool for treating a variety of bone and joint diseases without the risk of tissue rejection and surgery failure, as with current methods of bone replacement and implants,” Meretzki claimed.

Over 2 million bone-graft procedures are performed annually, and problems are endemic to most of them, Meretzki explained to The Times of Israel this week. A bone graft is a surgical procedure that replaces missing bone in the body. It may be needed when victims of particularly bad accidents find that their bones are too broken to be set in a cast. There are cases where bones are removed to prevent infection or other problems. In yet-other instances, doctors may have to remove bones that are not healing properly and are interfering with the body’s normal functions.

The elderly also constitute a large group with bone problems: Bones become brittle, infected, or diseased. Doctors, in triage manner, must cut away the “bad” bone in order to preserve the health, or even the life, of the patient. Here too, bone grafts come in.

In order to build a bone, a scaffold is constructed in the shape and form of the bone. Then, material to grow the bone material is inserted, and the graft is placed inside the body and held in place by pins or screws. Inside the body, a number of biological processes (Osteogenesis, Osteoinduction, and Osteoconduction) grow the bone. After a period of months — or even years, for complicated constructions — the new bone integrates into the body, and the screws are removed.

There are two general sources for the biological material needed to “start” a new bone: Autologous (or Autogenous) bone grafting involves utilizing bone obtained from the same individual receiving the graft, with bone harvested from non-essential bones (often from a portion of the pelvic bone) and placed into the scaffold. A second method of grafting is Allograft, which involves taking bone from sources other than the patient — such as cadavers that are “mined” for their bones.

Both methods have major drawbacks, including infections, hematoma, and — in the Allograft method — rejection of the implanted material by the body. As many as 20% of all bone grafts lead to serious problems, and, according to doctors, even among many of the other 80% of patients, pain is a major problem.

The Bonus BioGroup way to build bones avoids the complications and problems of both Autogenous and Allograft grafting. “We take cells from the body, usually by liposuction, and separate them into their specific components, to more easily and quickly take advantage of the regeneration process,” explains Meretzki. “At the same time, we make a 3-D image of the area that needs to be filled in — using a CAT scan or other method — and build a precise scaffold. We then add the cell components to our patented culture bioreactors, where the bones grow, outside the body. Once the bone is grown, we transplant it into the body.

“The bones are grown from the patient’s own cells, guaranteeing that they will not be rejected by the body,” Meretzki continued. “The result is a unique, 3-D, high-density bone graft based on multi-cell cultures, allowing the bone graft to be accepted by the patient better and faster in comparison to any other alternative.” By growing the bone outside the body, doctors have full control over the process, and can ensure that the development of the bone goes according to plan. This process ensures a minimum of complications once the bone is inserted into the body.

The “factory” where the scaffolds will be constructed and the bones grown, located in Haifa, should be ready later this year, said Meretzki, at which point the company will be ready to proceed to clinical trials on people. Until now, the company has been using animals to prove that its methods work; it utilizes the fat cells of humans to grow bones for animals with a bone deficit.

So far, Meretzki claimed, the method has worked quite well. “The establishment of the first facility in the world for growing human bone grafts, designed for human transplant, will be a key element in implementing the company’s unique technology,” he added. “Our system allows bone transplants that will be available on demand, fitting like a tailored suit, safer, less expensive, and providing a better outcome than any other solution available to date.”

Meretzki has degrees in biotechnology, chemical engineering, biology, and chemistry. Bonus BioGroup is his fourth company — and he is barely 40 years old. “I was founder and CEO of Pluristem Therapeutics, which was basically the work I did for my PhD at the Technion,” he said. Pluristem developed the technology to grow cells for non-allogenic cell-therapy products for “off the shelf” use based on human placenta, a non-controversial, non-embryonic, adult cell source that does not histocompatibility matching for patients.

“But the cell growth we did at Pluristem was much less sophisticated than the organ-generation work we are doing at Bonus BioGroup,” Meretzki said. “We have already shown we can build bone using this method, and I believe we will soon be able to develop cartilage. Then we can begin working on joint tissue, another application which, I believe, this technology will soon be able to be used for.”

Could the Bonus BioGroup method be used in the future to grow an organ — a kidney or even a heart? “Bone, which is inert, is complicated enough to grow, and there are far more complicated challenges to building a living organ, much beyond the reach of any technology today,” he said. Still Meretzki is willing to imagine a future where old, tired-out organs are replaced with freshly grown ones. After all, not long ago, the whole idea of what Meretzki is doing today seemed like science fiction, too.