What some people recognize as “fearlessness” in a successful company, is really just “persistence”.

Recently, I had the opportunity to pay a visit to Treace Medical Concepts (TMC) in sunny northeast Florida. After a full tour, I had the chance to meet with my old friend John Treace, and other leaders onsite.

I was eager to explore the unrivaled practices that TMC is using to transform segments of the Foot & Ankle surgery market.

First the setup.

TMC came out of nowhere to create the better bunion correction solution with a much lower failure rate. They have become a billion dollar startup from a standing start just a few years ago. (Read my interview with TMC in back 2015 for a glimpse into how it all started.)

So lets get into it… what makes TMC tick?

In no particular order, I found 8 ingredients in the secret sauce that TMC has created.

1/ Focus, Focus, Focus

Treace has created a focused “product first” culture. While they could easily have designed a full bag of 100 foot and ankle products (from halux fusion to total ankles) like many of their competitors, they choose to focus on key unsolved clinical areas in the foot and go deep.

They also have a surgeon focus which is exemplary. When each surgeon customer reaches a 100 cases, they memorialize this milestone on the wall of fame appropriately located outside the bioskills lab.

2/ People

The leaders are TMC are no-nonsense professionals who know how to execute the mission. There is no bureaucracy or meetings-to-have-meetings, or CYA at TMC. It feels like there is no wasted energy on things that don’t move the company and the products forward. Treace insists on a team committed to this culture and driving results.

3/ Iterative Processes

TMC is one of the rare companies in orthopedics that persistently iterates the product and procedure. The product teams are obsessed with improving outcomes for bunion patients. They are never content and constantly pushing themselves to make the products better and better. They conduct an average of two “R&D” cadaver labs each week for new product development. That’s 100 per year. Who does that? This product obsession behavior is more conducive to a software company that launches version 1.0 and now is working on version 14.2. (like Tesla upgrades my car every month). Rapid iterative R&D is near and dear to my heart as we did this at Ellipse Technologies with MAGEC. The ultimate beneficiary of this singular product focus is the patient and the surgeon.

4/ Use of Capital

A 2nd order effect of the product focus is streamlining. TMC employs a hybrid product configuration model of low cost instrument trays and sterile implant kits. This efficiency in capital deployed per sale allows TMC to leverage capital better than most orthopedic companies; remarkably they support their entire business with <40 sellable SKUs. This is the Southwest Airlines model brought into orthopedics.

Today, the majority of TMC’s R&D and Marketing resources are focused on iterating Lapiplasty®. Even with $150M in sales, they still only capture 5.5% of the knowable market. Another facet of TMC’s R&D and Marketing resources is dedicated to developing complementary products related to the bunion, such as their Adductoplasty® mid-foot correction system. The remaining chunk of TMC’s R&D and Marketing resources are focused in skunk works programs. Stay tuned.

5/ Sales Trajectory

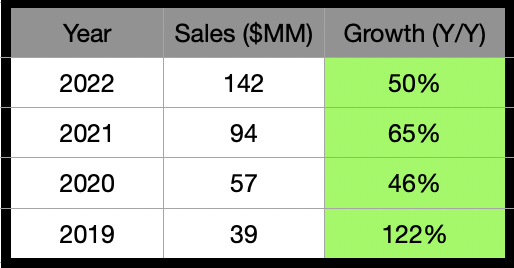

Results are the results. This trajectory of sales growth in orthopedics is rarely seen. Numbers are rounded to the nearest million and percentage for simplicity. You can find the actual SEC filings here.

For contrast, compare TMC’s Y/Y growth to other ortho companies Y/Y growth in the $100-$300M scale.

The sales theme at this years National Sales Meeting was “Mission Unstoppable”, a consistent mission-inspired theme for four years (note TMC’s symbolic use of Spartans representing their sales teams’ focus and expert training, allowing them to differentiate and win in the market).

6/ Startup Culture

I have been inside many companies where I can feel the “vibe”. TMC “feels” like a startup, even at their scale (over 150 employees in the office and ~270 in the field). A startup that takes chances and has a sense of urgency. It is rare for an orthopedic company of this size to behave like TMC. Most companies at this scale, especially if publicly owned, get conservative with a focus on protecting their existing legacy products, but TMC somehow maintains a fast-paced startup culture.

7/ Facilities

TMC’s facilities are brand new and state-of-the-art. Everything was purposely built for this “product first” culture. Probably the best cadaver skills labs and R&D prototyping labs I have seen. With a four-story building, TMC is utilizing two full levels today, and is building out a third floor that will be occupied soon, with an additional floor ready for future expansion.

8/ Board of Directors

You cannot find a group of Board member who has been more successful in orthopedics than the TMC Board. For decades, they have helped to create revolutionary products and procedures in orthopedics and, as a result, have created billions of dollars of shareholder equity.

A few companies that the Board has built:

- Richards Manufacturing, Memphis, TN (1970’s)

- Concept, Largo, FL (1980’s)

- Xomed Surgical, Jacksonville, FL (1990’s.)

- Wright Medical, Arlington, TN (2000’s)

- Kyphon, Sunnyvale, CA (2000’s)

Tiger Buford – retained recruiter dissecting orthopedics for you

Tiger Buford – retained recruiter dissecting orthopedics for you